The Impacts of Microfluidic Mixers on Diffusion

Microfluidics are an important technology for the advancement of biomedical diagnostics research and drug development. Due to the high surface to volume ratio of the control channels, there is much more laminar flow than turbulent flow through these channels. Mixing is a fundamental function of microfluidic devices primarily occurs through diffusion in laminar flow. This project was primarily concerned with the comparison of varying passive micromixers since these are typically the lowest cost designs and easiest to manufacture which is useful in reducing production costs. For this project, I worked with one partner to build and test four microfluidic mixing designs.

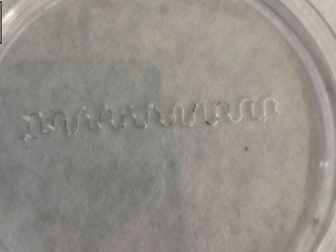

The four designs that were chosen are: A. T-mixer, B. Y-mixer, C. Serpentine mixer, and D. Tesla valve mixer. The T-mixer was primarily included as a control. The serpentine mixer is meant to increase the length of the channel while maintaining a small overall surface area for the mixer. The tesla valve was meant to create a back pressure through the valve to stir up the flow.

The devices were manufactured with designs created on Solidworks and printed on vinyl stickers. PDMS was then used to pour over the sticker to create the device. When the devices were developed, a co-flow was established between water and FITC-dextran. A LumaScope was then used to capture concentration profile along the length of the channel.

Unfortunately due to many sources of error with the production of the channels, the results do not seem viable. Bubbles were introduced in the channels during curation and the channels got altered because the vinyl stickers were hard to peel.

If you are interested in learning more about the creation of microfluidic devices or our results, please check out the final report for this project.